PDF list

- Garantiebestimmungen: click there to view details.

- VectorDigital product catalogue: click there to view details.

- Data sheet: click there to view details.

- Bedienungsanleitung: click there to view details.

- Technical Details: click there to view details.

- Warranty conditions: click there to view details.

Descript of Vector Schweißgerät NewYork 2500 Kombi AC/DC WIG 200 Puls Mit Plasmaschneider ALU TIG MMA E-Hand Inverter 5 in1 +Magnet Klein

Important functions & device information at a glance

Newyork 2500 |  | ||

Quick | Light industrial Application: Metal fabrication workshops Shipyards and offshore industry Maintenance and Repair Pipe welding outside Auto Body Light Industry | Process: DC TIG (GTAW) AC TIG (GTAW) Stick (MMA) Plasma Cutting | Input Power: 230V, 1-Phase Amperage Range: TIG/10-200A Stick/10-170A CUT/20-50A Rated Output at40 C (104 F): MMA:170A at 26.8V @ 25% Duty Cycle TIG: 200A at 18V @ 40% Duty Cycle CUT: 50A at 100V @ 40% Duty Cycle Weight: 11.5KG |

For TIG and Stick Welding

| A total solution of precise AC/DC TIG PLUS welding and plasma cutting machine |

| Newyork 2500 built base on the Mastertig System offers precise, expert AC/DC TIG welding process. It’s a precise aluminum welding specialist that suits all welded materials. Modular design allows you to build the package that best suits your needs. Newyork 2500 also comes with a 50A@60 heavy duty cycle plasma cutting power source. What you need for any metal welding or cutting works, you just get this combo machine and it’s all you needs.For TIG and Stick Welding.Easy operation and full functions: From the control panel allowing fast adjustment of all necessary controls for DC, AC TIG welding with either HF or contact ignition. It’s also very convenient to store or call out the welding parameters from the memory channels. |

Specialist Features

| Precision Arc Performance: | |

| ♦ DC+/DC-: Improved TIG starting. Now starts DC(-) to maintain a sharp tungsten. |  |

| ♦ Lift-Arc start provides AC or DC arc starting without the use of high frequency. | |

| ♦ Adjustable AC output frequency allows the operator to focus the arc minimizing the heat affected zone. | |

| ♦ Extended AC Balance Control helps maintain a pointed tungsten to direct the arc in the weld joint. | |

| ♦ Independent amplitude/amperage control allows EP and EN amperages to be set independently to precisely control heat input to the work and electrode. | |

| ♦ Multiple Waveshapes: | |

| ♦ Standard Squarewave for fast travel speeds and excellent puddle control,Sine wave for a traditional softer sounding arc,Triangular wave to reduce the heat input into the weld at low amperage.Soft squarewave for a soft buttery arc with maximum puddle control and good wetting action. | |

| ♦ Pilot Arc for superior arc performance and easy start. | |

| ♦ HF or Non-HF Arc ignition: reliable plasma arc initiation without high frequency. |  |

| ♦ Continuous Output Control: focus the arc for different material thickness. | |

| ♦ Rapid Arc Restrike: fast cutting through gaps, even expanded metal. | |

| ♦ Powerful with heavy duty: 200A @50%. | |

| ♦ 10 channels memory capacity | |

| Outstanding Quality: |

| ♦ Newly designed using the latest power electronic technology for improved reliability. |

| ♦ CE Certified. |

| ♦ 2 Years Warranty on parts , 5 Years Warranty on Transformer |

Technical specifications

| Description | VECTOR DIGITAL Newyork 2500 MULTIFUNCTION |

| Weight | 31 kg |

| Power Source Dimensions | L380mmxW160mmxH360mm |

| Cooling | Fan Cooled |

| Welder Type | Inverter Power Source |

| European Standards | EN 60974-1 / IEC 60974-1 |

| Number of Phases | 1 |

| Nominal Supply Voltage | 230V +/- 15% |

| Nominal Supply Frequency | 50/60Hz |

| Welding Current Range ( STICK Mode) | 10 - 170A |

| Welding Current Range ( TIG Mode) | 10 - 200A |

| Welding Current Range (CUT Mode) | 20 - 50A |

| Effective Input Current /STICK /TIG | 15.4A |

| Maximum Input Current/STICK/ TIG | 30.9A |

| Single Phase Generator Requirement | 10KVA |

| STICK (MMA) Welding Output, 40oC, 10 min. | 170A @ 25%, 26.8V 85A @ 100%, 23.4V |

| TIG (GTAW) Welding Output, 40oC, 10 min. | 200A @ 40%, 18V 126A @ 100%, 15V |

| Cutting Welding Output, 40oC, 10 min. | 50A @ 40%, 100V 25A @ 100%, 90V |

| Open circuit voltage | 60V DC |

| Open circuit voltage CUT | 250V DC |

| Protection Class | IP23 |

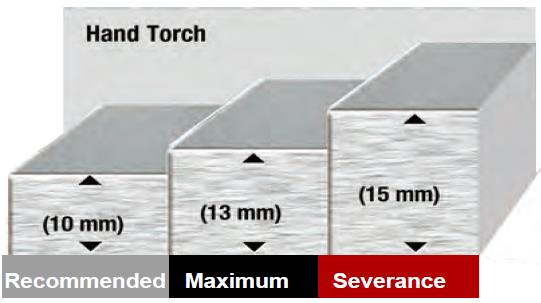

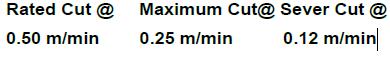

| CUT PERFORMANCE - MILD STEEL | |

|

|

| Big cutting power in a small package - the industry's most portable and powerful 40-amp plasma cutter offers 10mm. mild steel cutting.The unit offers easy connection to 115V or 230V input with Auto-Line technology and MVP Adapters. |  |

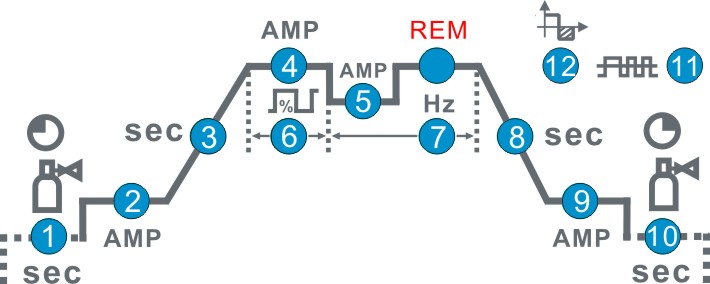

| General View of Control Panel |

| Control Panel Parameter Values | ||

| 1. RESET buttonr 2. Pulse Button 3. Trigger Mode Control Button 4. Process Selection Button | 5. Power ON Indicator 6. Thermal Overload Indicator 7.JOB and SAVE | 8.AC/DC Mode Button 9.Positive Control- Negative Control- Back Programming Button 10. Hot Start-Arcforce-Start time |

| General View of Contrl Panel(Continued) | ||

| ||

| Item | Symbol | Description |

| 1 | Gas Pre-Flow | Absolute setting range 0.1s to 20s (0.1S increments) |

| 2 | Initial Current | The main current Setting range 10AMP to 100AMP |

| 3 | Up Slope | Setting ranges :0.1S-10S (0.1S increments) |

| 4 | Peak Current | Setting ranges 10AMP to 200AMP (DC TIG mode), 10 to 200A (AC HF TIG mode) |

| 5 | Base Current | Setting ranges 10AMP to 200AMP (DC TIG mode), 10AMP to 200AMP (AC HF TIG mode) |

| 6 | Pulse Width | Setting ranges 10%-90% |

| 7 | PulseFrequency | Setting ranges 1HZ -200HZ |

| 8 | Down Slope | Setting ranges 0.1-10s |

| 9 | End current | Setting ranges 10A-100A |

| 10 | Post Flow | Setting ranges 1-20S |

| 11 | AC Frequency | Setting ranges 50HZ-200HZ |

| 12 | Wave Balance | Setting arranges 10%-50% |

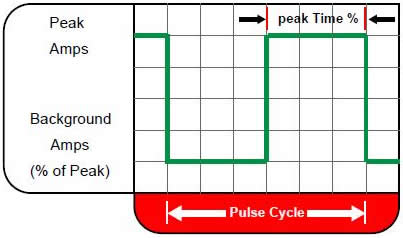

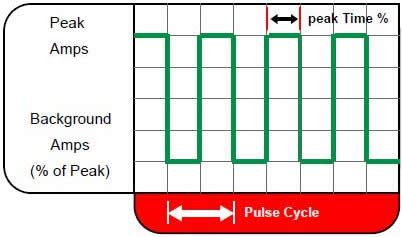

| DC TIG-Pulse | |

| ♦ High Speed DC TIG-Pulse Controls ♦ PPS Pulses per second (Hz): DC=0.1- 5,000 PPS ♦ % ON-% Peak Time: 5-95% (Controls the amount of time during each pulse cycle at the PEAK amperage.) ♦ Background Amps: 5-99% (Sets the low-pulse amperage value as a % of the Peak Amps.) | |

| CONVENTIONAL PULSED TIG | HIGH SPEED PULSED TIG |

|

|

| Typically from 1 to 10 PPS. Provides a heating and cooling effect on the weld puddle and can reduce distortion by lowering the average amperage.This heating and cooling effect also produces a distinct ripple pattern in the weld bead. The relationship between pulse frequency and travel speed determines the distance between the ripples. Slow pulsing can also be coordinated with filler metal addition and increase overall control of the weld puddle | IIn excess of 40 PPS, Pulsed TIG becomes more audible than visible-causing increased puddle agitation for a better as-welded microstructure.Pulsing the weld current at high speeds- between a high Peak and a low Background amperage- can also constrict and focus the arc. This results in maximum arc stability, increased penetration and increased travel speeds(Common Range: 100-500 PPS).The Arc-Sharpening effects of high speed pulsing are expanded to new dimensions. The ability to pulse at 5,000 PPS further enhances arc stability and concentration potential-which is extremely beneficial to automation wheremaximum travel tspeeds are required. |

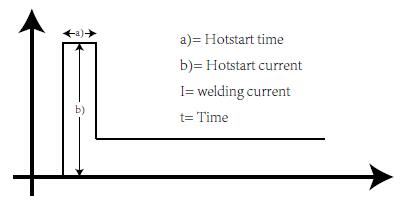

| Hot Start | |

| Hot Start Function reliably ignites the electrode and melts perfectly to ensure the best quality even at the start of the seam. this solution makes lack of fusion and cold welds a thing of the past and significantly reduces weld reinforcement.Adjust the hot start current here and the time here. |  |

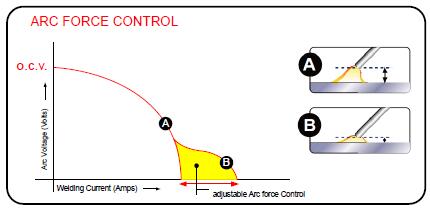

| Arcforce correction (welding characteristics) | |

| During the welding process, arcforce prevents the electrode sticking in the weld pool with increases in current. this makes it easier to weld large-drop melting electrode types at low current strengths with a short arc in particular. |  |

Accessories

| For Standard accessories | ||||

|

|

|

|

|

| TIG torch: WP-26 Gas connector: M16 Cable length 3M 5-pin control coupler | Electrode holder with cable 3M/200A | AG 60-Torch/4.5M | Earth clamp with cable 3m | Reducing valve AW2000 |

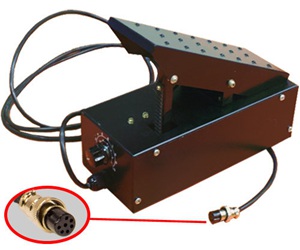

| For Optional accessories | ||||

|

|

|

|

|

| Argon gas regular | Water-cooling unit: wc-100 Operating Voltage:230V 50/60Hz Rated Power:260W Cooling Power:1.5KW(1L/MIN) Tank Volume:6.5L | TIG torch: DGT 26 Cooling Method: Air-Cooled Rating: DC 200A AC 125A Duty Cycle: 35% Electrode Size: 1.0-4.0 | Trolley | Foot Pedal Trolley: 5-pin aviation plug |

| Welding Type: | TIG DC |

| Plasma cutting: | CUT contact |

| Brand: | S-Series |

| Shipping weight: | 12,90 Kg |

| Product weight: | 11,85 Kg |

| Dimensions(length × width × height): | 59,00 × 46,00 × 41,00 cm |

| Ausgangsstrom WIG | 10-200 A |

| Ausgangsstrom MMA/ARC | 10-200 A |

| Ausgangsstrom Plasma/CUT | 10-45 A |

| Einschaltdauer WIG | 60% bei 200 A |

| Einschaltdauer MMA/ARC | 60% bei 200 A |

| Einschaltdauer Plasma/CUT | 60% bei 45 A |

| Leerlaufspannung | 56 V |

| Schutzklasse | IP21S |

| Isolationsklasse | F |

| Eingangsspannung | 230 V AC (+-15%) / 1 ~ |

| Eingangsfrequenz | 50/60 Hz |

| Abzusichern mit min. | 16 A |

| Maximaler Eingangsstrom | 27 A |

| Maximale Eingangsleistung | 6,2 kVA |

| Empfohlene Generatorleistung | > 7 kVA / 1 ~ |

| Gewicht | 20,9 kg |

| Größe L x B x H mm ohne Griff | 500 x 330 x 320 |

| Größe L x B x H mm mit Griff | 500 x 330 x 360 |

| Netzstecker-Typ | SchuKo-Bauart CEE 7/7 |

| Normen | IEC 60 974-1 ; CE ; S-Kennzeichen |

| TIG accessories |

| TIG-Torch "WP-26" 4,5 Meter [Art.# SB2000-01] 4 Gas Nozzles. Size: 4 [Art.# ZT3010-01], 5 [Art.# ZT3010-04], 6 [Art.# ZT3010-07], 7 [Art.# ZT3010-10] 4 Collets. Größe 1,6 [Art.# ZT3000-04] and 2,4 [Art.# ZT3000-07] 4 Colletbodys. Größe 1,6 [Art.# ZT3001-04] and 2,4 [Art.# ZT3001-07] One short [Art.# ZT3030-02] and one long [Art.# ZT3030-01] Tungsten head |

| CUT accessories |

| Plasma-Torch "AG-60" 4,50 Meter [Art.# SB2110-01] 5 Plasma Nozzles tip AG60 [Art.# ZC3110-01] 5 Plasmaelectrodes AG60 [Art.# ZC3111-01] 3 Shield cups AG60 [Art.# ZC3112-01] * 1 set already assembled on torch |

| Watertrap with gauge [Art.# ZC3150] |

| Gas-Hose: 3 m [Art.# ZO3450] |

| Ground cable 3 Meter [Art.# CA2350-01] |

| Electrode cable for STICK 3 Meter [Art.# CA2300-01] |

English

English 简体中文

简体中文